Definition and operating principles of Pneumatic Actuators

What is a pneumatic actuator

The pneumatic actuators, or pneumatic cylinders as they are also referred to, are highly reliable and safe motion control devices that convert energy of compressed air or gas into rotary or linear motion that regulates one or more final control elements. They are used as a form of automation control to reduce human interaction with the internal mechanisms of a system. This aspect is particularly advantageous for automatic modulation and emergency stops.

The movement of a pneumatic actuator can be linear or rotary, depending on the design of the device:

Linear pneumatic actuators

A linear pneumatic actuator uses an external compression force, such as compressed air or gas, to move a piston inside a hollow cylinder and create pressure. This generates a linear force relative to the pressure difference of the piston multiplied by its surface, which is used to move a load along a straight line.

Rotary pneumatic actuators

A rotary pneumatic actuator is a pneumatic cylinder used to provide rotation or angular motion, allowing a stroke in an oscillating motion through a defined angle. Rotary pneumatic actuators are heavy duty devices that provide relatively high force (torque) for size.

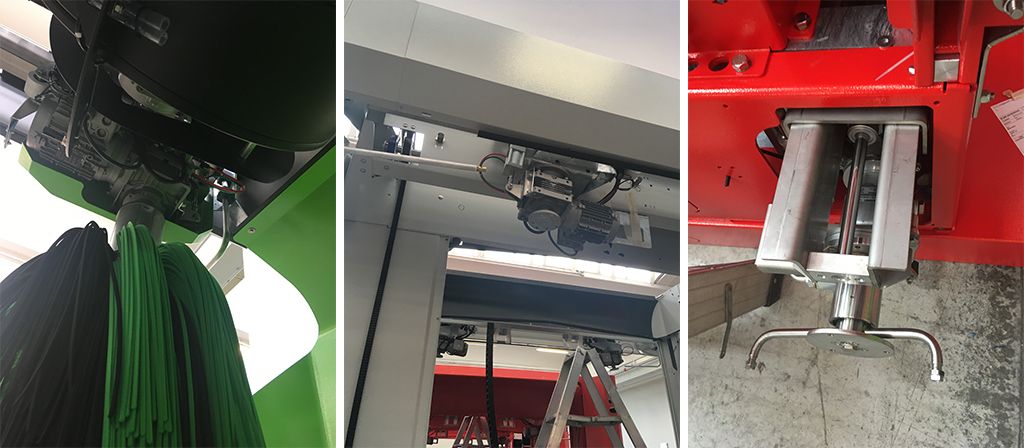

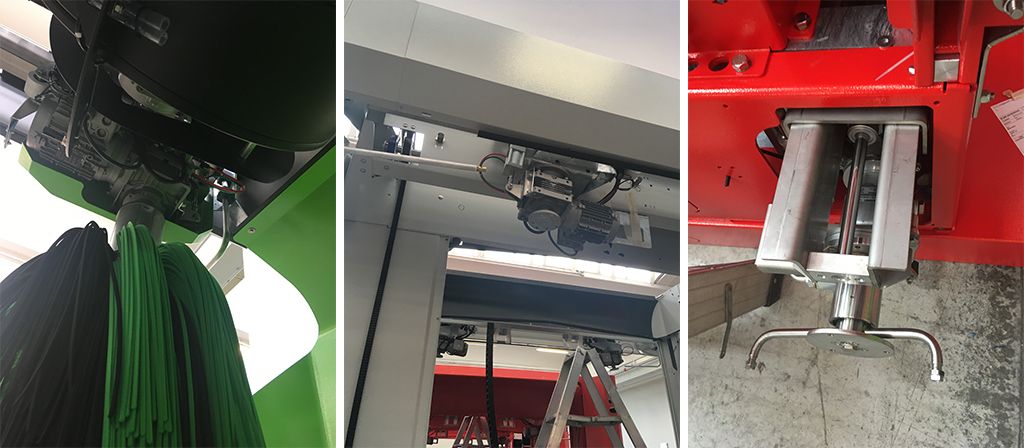

Applications of Pneumatic Actuators

The pneumatic actuators have a wide variety of applications: packaging and production machinery, machines for the pharmaceutical sector, wood and plastic processing, rubber injection, glass processing. They are used in the transport industry such as railway and aeronautical applications. They are also essential devices in many other industrial applications.

Pneumatic actuators vs electric actuators

While pneumatic actuators work thanks to pressurized air, electric actuators work thanks to electricity. Electric actuators consist of a screw, coupler and engines: the screw turns and moves a nut, which makes the interfacing pole or carriage shift the heap. Although pneumatic and electric actuators have comparable utilization, they are not directly interchangeable in all industries. These two types of actuators also differ in the following aspects:

- Cost: pneumatic actuators have lower initial costs than the electric variety. Pneumatic cylinders are the most cost-efficient when the compressor size matches the number of cylinders it’s powering.

- Force: in pneumatic actuators, speed and thrust are positively linked, meaning as one increase, the other does as well. In electric actuators, thrust and speed do not have the same link, as one decreases as the other increases

- Control: Pneumatic actuators are better for industries that need force, electric actuators provide more accurate control and positioning.

-

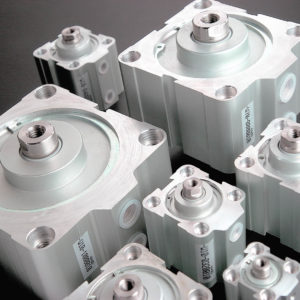

ISO 21287 compact cylinders

Food industry, ISO 21287 compact cylinders, Moulding machinery, Standard products, Transport, Welding systems, Wood working machinery0,00€ Add to cart -

-

-

Microcylinders ISO 6432

Food industry, Microcylinders ISO 6432, Moulding machinery, Standard products, Transport, Wood working machinery0,00€ Add to cart -

-

-

ISO 15552 cylinders

Aggressive environments, Extreme temperatures, Food industry, ISO 15552 cylinders, Moulding machinery, Transport, Welding systems, Wood working machinery0,00€ Add to cart -

Short stroke cylinders

Food industry, Moulding machinery, Short stroke cylinders, Standard products, Transport, Welding systems, Wood working machinery0,00€ Add to cart -

-

Advantages of Pneumatic Actuators

Let’s now discover the main benefits deriving from the use of a pneumatic actuator that make it one of the most popular and used mechanical devices in the industrial field.

High strength and speed of movement

Pneumatic actuators can provide high force and speed of motion when used in linear motion control applications. This is due to the use of pressure and air flow inside the device.

High resistance

Pneumatic actuators are not affected by overheating problems even if used in applications characterized by intensive use. These devices are able to withstand constant pressures compared to alternative devices and therefore offer greater strength and durability.

High reliability

In terms of functionality, the pneumatic actuator is considered highly reliable. This is mainly thanks to the high control that can be maintained on the conversion of gas into energy. Pneumatic actuators therefore combine two fundamental characteristics that guarantee a long life: resistance and reliability.

Clean technology

Pneumatic actuators are the most suitable device for use in applications where hygiene is essential. This is guaranteed by the use of air over fluids: compressed air is in fact free of harmful chemicals and therefore protects the application from contamination. This is a fundamental aspect in the pharmaceutical and food and beverage industries.

Affordability

Thanks to the simple installation and maintenance, the pneumatic actuator is often considered the most convenient choice when it comes to industrial applications.

Conclusions

Mec Fluid 2 produces a wide range of pneumatic actuators to support different configuration needs and according to widely adopted and international standards (ISO). The most commonly used pneumatic actuators Mec Fluid 2 adopt a surface treatment, i.e. polyurethane powder coating, which guarantees high resistance to corrosion. Wide configuration possibilities are available which make pneumatic actuators suitable for various applications in all industrial sectors.