The use of pneumatic actuators in the welding sector

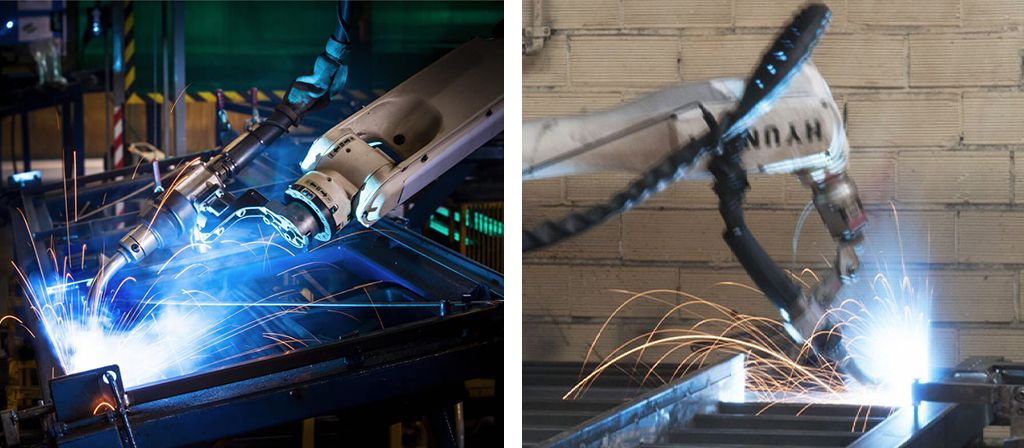

With the aim of meeting the expectations of customers in terms of improved performance, manufacturing companies are embracing process automation technologies in order to increase their productivity by reducing costs and improving product quality. Industrial robots are now present in many production processes such as robotic welding applications where speed and accuracy are key features. An example is the automotive body-in-white applications where joining sections of metal parts to form the car frame requires hundreds of welds.

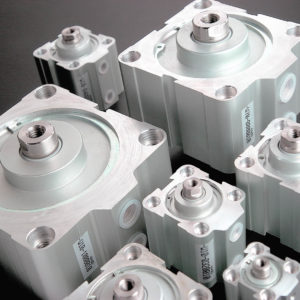

Many manufacturers decide to control their welding equipment by using pneumatic actuators to actuate the weld guns and apply the amount of force necessary to complete the weld cycle. As a component, the pneumatic actuator guarantees easy installation and a very competitive purchase cost.

In terms of performance, the pneumatic actuators guarantee high resistance to high temperatures and mechanical vibrations, allowing excellent weld quality. Pneumatic systems require only planned maintenance activities and, due to their constitutive characteristics, simplify the operations. The result is a consistent system with no losses or misalignments in regulation.

How to choose the most suitable pneumatic actuator

When selecting a pneumatic actuator, it is necessary to take into account that it must be able to perform the full motion profile expected of the weld gun. The pneumatic actuator also needs to be able to meet the speed requirements of the welding process by creating and maintaining the proper force. The sizing activity of the welding system must consider actuators that guarantee repeatable and qualitative welds for the entire expected duration. Finally, you need to consider the full motion required to load and unload parts, the moving distance to complete the weld sequence, the number of welds required for each sequence, and the number of sequences to handle in an hour.

To satisfy these requirements it is therefore necessary to choose between various types of actuators available such as:

- Multiple stroke actuators

- Adjustable stroke actuators

- Multistage actuators

-

ISO 15552 cylinders

Aggressive environments, Extreme temperatures, Food industry, ISO 15552 cylinders, Moulding machinery, Transport, Welding systems, Wood working machinery0,00€ Add to cart -

ISO 21287 compact cylinders

Food industry, ISO 21287 compact cylinders, Moulding machinery, Standard products, Transport, Welding systems, Wood working machinery0,00€ Add to cart -

Short stroke cylinders

Food industry, Moulding machinery, Short stroke cylinders, Standard products, Transport, Welding systems, Wood working machinery0,00€ Add to cart

Advantages of using pneumatic actuators in the welding sector

Pneumatic actuators (or cylinders) are the ideal solution for providing controlled motion to all machines and plants used for industrial automation applications. In particular, the actuators are ideal for welding clamp applications where high force control, accuracy and speed are required. Among these we include:

- Spot welding

- Robotic welding

- Welding pins

- Tightening

These products guarantee an increase of the performance of the machines on which they are installed in compliance with the main needs of this industrial unit in terms of resistance, customization, regulation, rigidity, precision and reliability.

Conclusions

The choice of the most suitable pneumatic actuator for a welding system depends on a very high number of factors. In Mec Fluid 2 we have a commercial technical team that can provide support in choosing the best automation technology in the welding field and for any kind of application. We will help you to find the most suitable solution.