Pneumatic Cylinders: a complete Guide for the Industry

Introduction to Pneumatic Cylinders

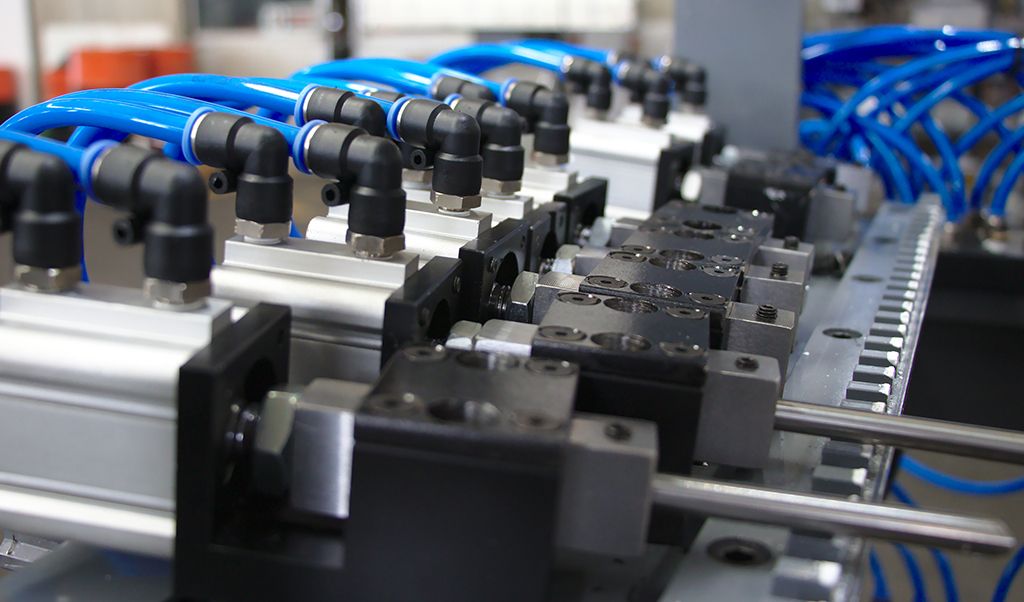

In the industrial context, pneumatic cylinders constitute a fundamental component. These devices play the important function of converting the energy derived from compressed air into mechanical motion, offering highly efficient and reliable solutions for a diverse range of industrial applications.

Distinctive Features of Pneumatic Cylinders

ISO 15552 Cylinders: Versatility and Reliability

ISO 15552 pneumatic cylinders, also known as VDMA 24562 cylinders are renowned for their versatility. With options that include heads made of acetal resin, powder-coated aluminum, or stainless steel, these cylinders are suitable for chemical, food, pharmaceutical, and various other industrial environments. Their resilience in aggressive environments or the need for periodic cleaning and sanitization of machinery makes them the ideal component for many industrial applications.

ISO 15552 pneumatic cylinders, represent a category of highly standardized and versatile cylinders in the field of industrial automation. These cylinders conform to ISO 15552 standards, which establish the technical specifications and dimensions to ensure interchangeability and consistency among the various manufacturers.

The key features and benefits of ISO 15552 cylinders include:

- Standardization: ISO 15552 standards ensure consistency in cylinder dimensions and specifications, simplifying the selection and integration of these devices into automated systems.

- Robust Design: ISO 15552 cylinders are constructed with high-quality materials and designed to withstand common mechanical and environmental stresses. This makes them suitable for a wide range of industrial applications.

- Wide Range of Sizes: These cylinders are available in a wide range of diameters and stroke lengths, allowing for the selection of the most suitable cylinder for a specific application.

- Ease of Maintenance: The modular and standardized design of ISO 15552 cylinders simplifies maintenance and component replacement, reducing machine downtime.

- Versatility: They are suitable for a variety of industrial applications, including material handling systems, processing machinery, packaging systems, and more.

- Reliability: Thanks to their robust design and compliance with international standards, these cylinders are known for their long-term reliability.

- Efficiency: Due to their advanced design, they ensure precise and repeatable movements, minimizing energy wastage and ensuring reliable operation over time.

The adoption of ISO 15552 cylinders can contribute significantly to the optimization of industrial processes, improving the efficiency and the operational consistency. Their standardization facilitates the design and maintenance of automated systems, allowing companies to reduce operating costs and improve overall productivity. Furthermore, their robustness makes them an ideal choice for demanding industrial environments.

Advantages and Benefits of Pneumatic Cylinders in Industry

In the industrial world, efficiency and reliability are key elements for maintaining consistent, high-quality production. One technology that has proven itself up to the task is the use of pneumatic cylinders. These mechanical devices, also known as air cylinders, use compressed air to generate reciprocating motion, making them invaluable in a wide range of industrial applications. Below are some of the main advantages offered by pneumatic cylinders in industry:

Speed and Precision

Pneumatic cylinders excel in providing rapid and precise motion control. Whether it’s moving a conveyor belt, controlling a robotic arm, or operating a packaging machine, these cylinders offer exceptional speed and precision. This allows manufacturers to optimize their production processes, leading to increased output and product quality.

Cost Efficiency

Compressed air, the driving force behind pneumatic cylinders, is often readily available in industrial environments. This makes pneumatic systems cost-effective to implement and operate. Unlike some alternatives, pneumatic systems require minimal infrastructure and are relatively easy to maintain, translating to lower overall costs.

Ease of Integration

Integrating pneumatic cylinders into existing industrial setups is generally straightforward. Their simple design and standardized interfaces make installation and maintenance relatively hassle-free. This means manufacturers can quickly implement pneumatic systems without significant downtime or costly modifications.

Energy Efficiency

Pneumatic systems excel in energy efficiency by utilizing compressed air only when in use, allowing precise control of energy consumption. Additionally, modern pneumatic components are designed with energy-saving features that effectively reduce air consumption, making them an environmentally friendly choice.

Cleanliness and Contamination-Free Operation

Pneumatic systems are ideal for industries where cleanliness and contamination control are critical, such as the food and pharmaceutical sectors. Since they rely on compressed air, these systems eliminate the potential risk of contamination from hydraulic fluids, ensuring that the products remain uncontaminated and safe for consumption.

These advantages make pneumatic cylinders a preferred choice for many industrial sectors. Implementing pneumatic systems can lead to significant improvements in operational efficiency while reducing costs and ensuring a safe and reliable working environment.

Applications in the Chemical, Food, and Pharmaceutical Sectors

The resistance to chemical agents of pneumatic cylinders makes them particularly suitable for demanding applications in sectors such as chemical, food, and pharmaceutical industries. Their robustness and reliability make them a preferred choice for these environments.

Tips for Selecting the Right Cylinder Model

Choosing the most suitable pneumatic cylinder model depends on various factors, including specific production requirements, available space, and environmental conditions. Considering all these variables is essential to ensure an optimal and durable solution.

Mec Fluid 2: Leading in Pneumatic Component Design

Mec Fluid 2 has established itself as a leader in the field of pneumatic cylinders, offering innovative and high-quality solutions. Our specialization in designing and manufacturing pneumatic components for compressed air and vacuum automation makes our company a trusted partner for industrial companies.

Maintenance and Care of Pneumatic Cylinders

To ensure maximum efficiency and longevity of pneumatic cylinders, it is crucial to follow the maintenance guidelines. Consistent practices such as regular cleaning, lubrication, and timely replacement of worn parts are indispensable for keeping cylinders in perfect working condition.

Innovations and Future Developments

The world of pneumatic cylinders is continually evolving. With the advent of new technologies and materials, future cylinders are expected to be even more efficient, durable, and versatile. Companies that stay up-to-date on these developments will be better positioned to harness the advantages offered by these innovations.

Safety in Using Pneumatic Cylinders

Safety is a priority when it comes to industrial components. Pneumatic cylinders, when used correctly, offer a high level of safety. However, it is essential to follow manufacturer guidelines and recommendations to ensure safe and trouble-free operation.

Conclusion

Pneumatic cylinders represent an essential solution for many industrial applications. Their efficiency, reliability, and versatility make them a preferred choice for companies looking to optimize their operations and ensure maximum production quality. In this context, Mec Fluid 2 emerges as a trusted partner. Within Mec Fluid 2, a dedicated technical sales team provides support in selecting the most suitable pneumatic cylinders for customers’ specific operational needs. Our priority is to ensure that each customer finds the most suitable solution for their requirements, thus ensuring process optimization and return on investment. With the experience and expertise of our team, we guide you in your choice, ensuring that you find exactly what you need for your industrial operations.