Definition and operating principles of the Pressure Boosters

Pressure Boosters

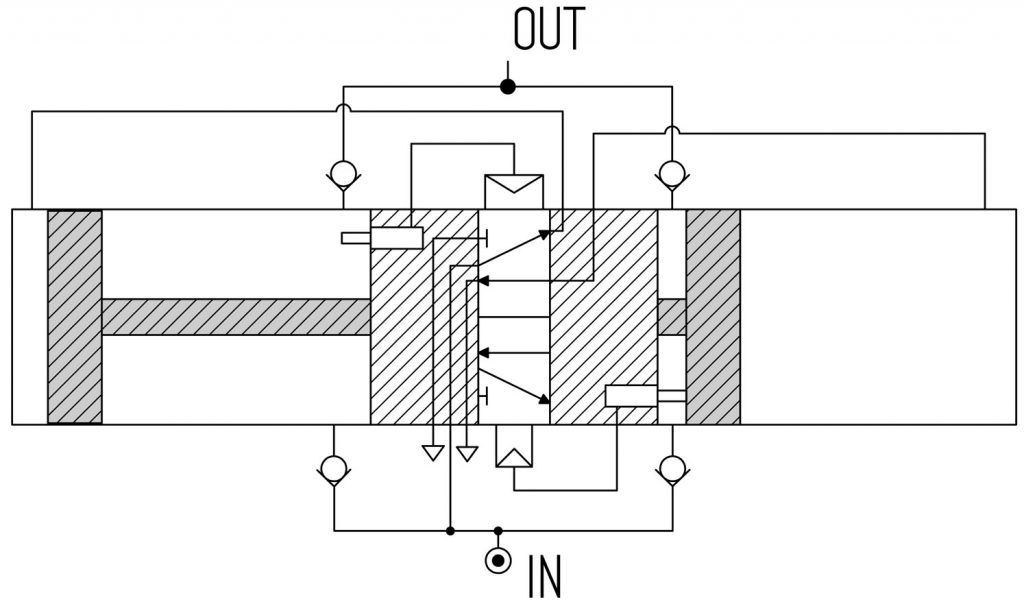

Definition and operating principles of the Pressure booster: a pressure booster is an automatic device that compresses air to give a higher outlet pressure than the inlet pressure. It is normally used to locally intensify the inlet pressure of one or more actuators. As it is entirely pneumatic, the pressure booster can be used when electric devices are not recommended. A pressure booster converts compressed air into high pressure using the principle of differential areas. No electrical connection and no lubrication is required.

The outlet pressure corresponds to the set air pressure multiplied by the transmission ratio of the booster: through a pressure regulator it is possible to manage the outlet pressure. The pressure boosters are equipped with non-return valves that allow the outlet pressure to be maintained even when the compressed air supply is interrupted. It is therefore necessary to switch off the power supply and unload the circuit before carrying out any work on the device. In order to avoid fluctuations in the outlet pressure it is advisable to install a tank after the booster.

When the booster is pressurized with compressed air, the higher pressure in the booster opens the non-return valve and air is allowed to flow into the secondary side through the piston. The outlet pressure p2 can be up to FOUR times greater than the inlet pressure p1. The pressure booster starts automatically when the supply pressure is applied and the desired outlet pressure has not yet been reached. When the set outlet pressure is reached, the pressure multiplier switches to energy-saving mode but restarts automatically if the pressure drops during system operation.

The pressure boosters are not suitable as replacement compressors, as the wear of the seals and the drive piston increases significantly if used continuously without interruptions.

Connection to the compressed air network

In the compressed air inlet line towards the pressure booster, the use of a 3/2 valve is recommended. This must not be opened until the inlet pressure is applied. In order to ensure a safe discharge of the output pressure it is recommended to connect a 3/2 valve also to the output pressure side of the booster.

-

Pressure Boosters 1-2

Compression ratio 1-2, Moulding machinery, Standard products, Transport, Welding systems, Wood working machinery0,00€ Add to cart -

Pressure Boosters 1-3

Compression ratio 1-3, Moulding machinery, Standard products, Transport, Welding systems, Wood working machinery0,00€ Add to cart -

Pressure Boosters 1-4

Compression ratio 1-4, Moulding machinery, Standard products, Transport, Welding systems, Wood working machinery0,00€ Add to cart

Benefits deriving from the use of pressure boosters

The use of pressure multipliers within pneumatic systems is highly appreciated for the resulting advantages, the main ones being the following:

- It does not require an electric power supply

- Compressed air lubrication is not required

- The pressure is maintained without any energy consumption

- Ideal for START / STOP applications under pressure

- Automatic start in case of downstream leak

- Adjustable stall pressure

- Easy to incorporate and use

- Easy implementation of automatic controls

Applications of pressure multipliers

Pressure boosters are used in various industrial sectors, we analyze below some applications of use:

- Testing with high pressure air on valves, fittings, pipes, tanks

- Leak test with air

- Need to increase the force of pneumatic cylinders

- Accumulator loading

- Airbag testing

- Gas injection (foaming machines)

Conclusions

Mec Fluid 2 designs and manufactures pressure boosters characterized by a maximum outlet pressure of 40 bar and by a minimum occupation of space. The devices can be supplied with or without pressure regulator. Mec Fluid 2 pressure boosters are available with compression ratios 1: 2, 1: 3 and 1: 4, do not require dedicated or additional compressors and do not require electrical connections.