The use of pneumatic cylinders in the transport sector

The transport sector refers to the transport industry specializing in the production of vehicles such as trucks, buses and trains. The use of pneumatic cylinders in this industry refers to the following operating contexts:

- Opening and closing of train doors

- Opening and closing of sides and tarpaulin covers on trailers and semi-trailers

- Seat adjustment

- Ventilation controls

- Vacuum management systems for toilets

- Control of doors or cabinet doors

- Handling and control of rail applications

- systems for managing the pressure in the tires of heavy vehicles

The transport sector is characterized by different working conditions in terms of temperature, vibration, or control voltage range. By designing a machine or application for the transport sector, that implements pneumatic cylinders, these different conditions must be considered. In the next paragraphs we will highlight the details of the working conditions of the pneumatic cylinders within these plants

Pneumatic cylinders and extreme temperatures

Temperature is a challenge for any plant and machine that works in an extremely cold or hot environment. In this paragraph we will explain what the problems and challenges can be in case of machines that are located in environment’s with very low or high temperatures, a very frequent case in vehicle production.

Use of pneumatic cylinders at low temperatures

What actually happens to a pneumatic cylinder in extreme cold conditions? The elasticity of the seals is reduced, the grease in the cylinder becomes viscous and there is the possibility of ice crystals forming on the piston rod. This certainly influences the operation of the cylinder. Due to the reduced elasticity, the air start to leak at the seal because it no longer fits as well on the piston rod. If the grease becomes more viscous and therefore thicker, the operation of the cylinder is less smooth. There is also a higher breakaway torque of the piston in the cylinder: the piston overcomes its resistance and shoots forward. As for ice crystals, if they are deposited on the piston rod they can cause grooves (wear) in the seal.

Use of pneumatic cylinders at high temperatures

Even at high temperatures it is necessary to consider a number of challenges. The main one is the variation in the resistance of the pneumatic cylinders when the temperature rises. At high temperatures, the cylinder components that are most under stress are the seals and lubricants. The lubricant becomes more thinner and reduces its performance. Consequently, the resistance between the piston and the seal increases. Furthermore, at a high temperature the cylinder seals deteriorate and lose their effectiveness.

Pneumatic cylinders and vibrations

It is important to consider that any complex system or plant is composed of mechanical components subject to problems such as vibrations. In a well-designed system, the vibrations are not related to the displacement action of the pneumatic controls, the linear movement of the cylinders, the rotation of pumps and motors. However, mechanical imbalance, which causes vibrations, is often the cause of pneumatic problems that maintenance workers must resolve

-

Microcylinders ISO 6432

Food industry, Microcylinders ISO 6432, Moulding machinery, Standard products, Transport, Wood working machinery0,00€ Add to cart -

ISO 15552 cylinders

Aggressive environments, Extreme temperatures, Food industry, ISO 15552 cylinders, Moulding machinery, Transport, Welding systems, Wood working machinery0,00€ Add to cart -

-

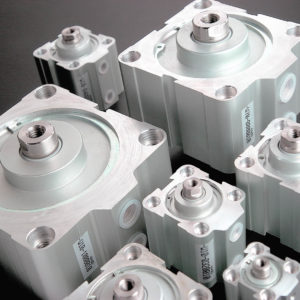

ISO 21287 compact cylinders

Food industry, ISO 21287 compact cylinders, Moulding machinery, Standard products, Transport, Welding systems, Wood working machinery0,00€ Add to cart -

-

Short stroke cylinders

Food industry, Moulding machinery, Short stroke cylinders, Standard products, Transport, Welding systems, Wood working machinery0,00€ Add to cart

Characteristics of pneumatic cylinders for the transport sector

After analyzing the issues and problems to be addressed in the case of the application of pneumatic cylinders in the transport industry, we analyze the main characteristics that the cylinder must have in order to best meet the needs of use.

Corrosion resistance

The products used within the transport sector must work in an operational context characterized by high corrosivity or the need for frequent washing of components with very aggressive chemical cleaning agents and substances. The cylinders used in this area are built with specific materials and surface treated to resist the presence of aggressive chemicals. The main features of these products are:

- Easy maintenance, cleaning, disassembly, and reassembly

- Resistant materials that comply with current standards

- Corrosion resistance thanks to the materials used and / or specific surface treatments

- Use of profiles and shapes suitable for simplifying cleaning / maintenance operations

Possibility of working at low and / or high temperatures

The transport sector requires the use of suitable products to ensure proper operation is maintained in the face of particularly low or high operating temperatures. The operating contexts of application vary from extremely low temperatures to extremely high temperatures up to 150 °C. The cylinders used in these conditions require the use of components characterized by high resistance. These are special products characterized by the use of materials, components and lubricants suitable for working at both high and low temperatures.

-

Pressure Boosters 1-2

Compression ratio 1-2, Moulding machinery, Standard products, Transport, Welding systems, Wood working machinery0,00€ Add to cart -

Pressure Boosters 1-3

Compression ratio 1-3, Moulding machinery, Standard products, Transport, Welding systems, Wood working machinery0,00€ Add to cart -

Pressure Boosters 1-4

Compression ratio 1-4, Moulding machinery, Standard products, Transport, Welding systems, Wood working machinery0,00€ Add to cart

Conclusions

Mec Fluid 2 produces customized pneumatic cylinders suitable for use in the transport industry. Mec Fluid 2 pneumatic cylinders meet the needs of this industry in terms of resistance, reliability and customization, guaranteeing the possibility of choosing solutions to simplify maintenance operations.